Services

Laboratory and technical services of dinamotor engineering

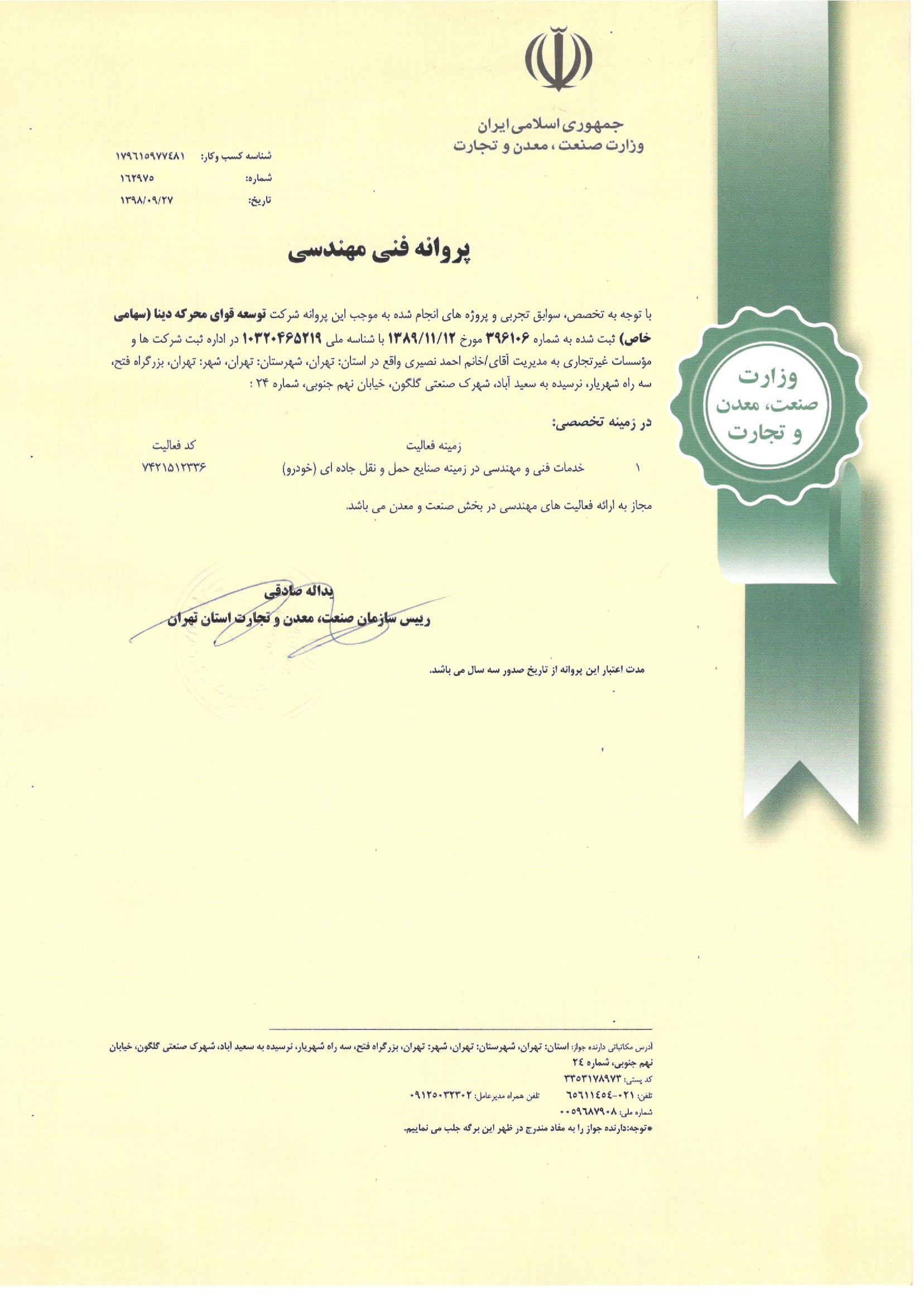

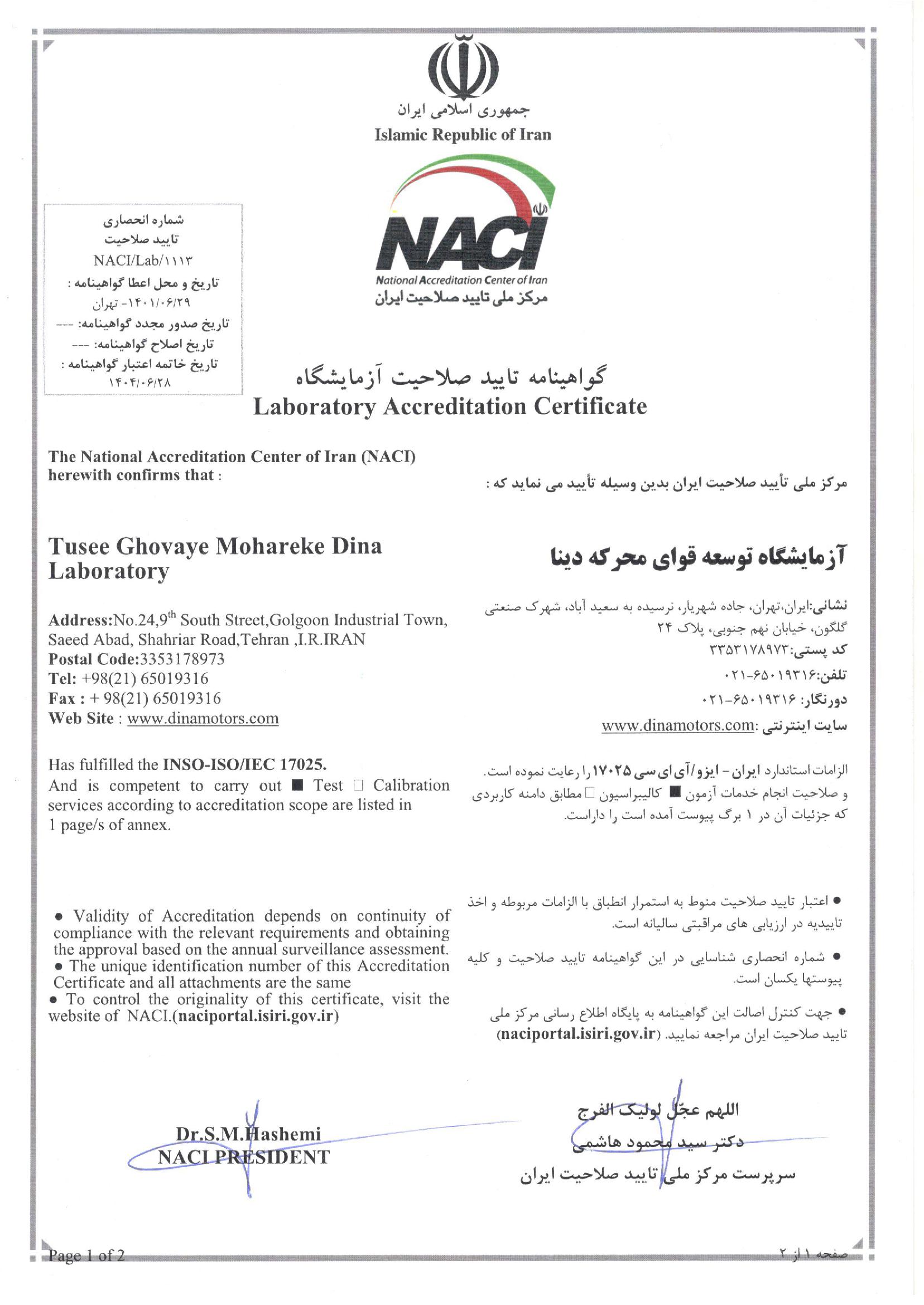

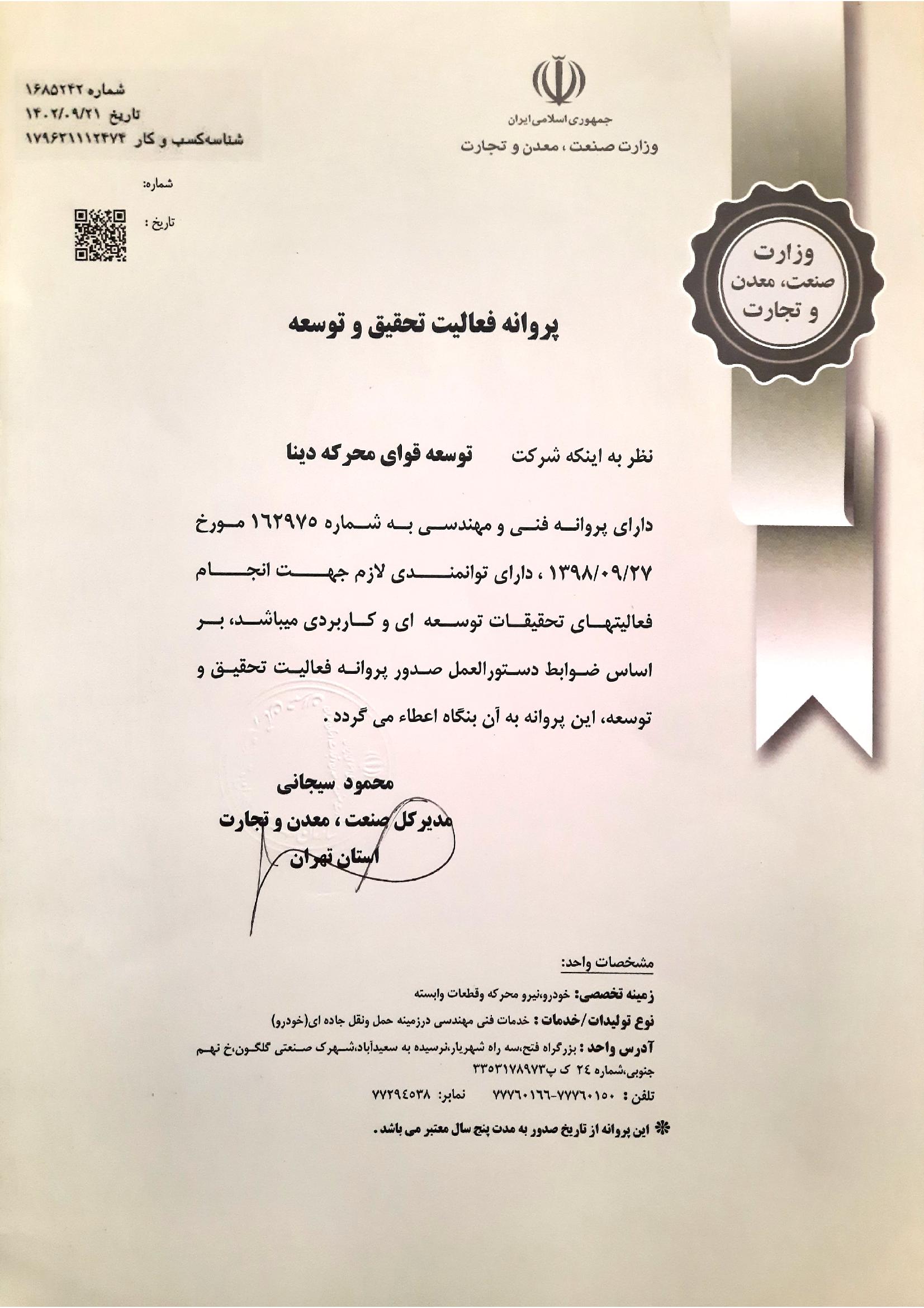

Since 2014, Dina Powertrain Development Company (DinaMotors) has launched testing activities using specialized testing equipment for engine and its components, entirely developed by our in-house engineering team. In 2016, DinaMotors became a partner laboratory of the Iran’s National Standards Organization and obtained ISO/IEC 17025 laboratory quality management certification. Since then, we have collaborated extensively with various industries, including prominent automotive manufacturers. Our expertise in designing and manufacturing testing equipment, combined with our success in conducting a variety of engine and component tests, allows us to support national industries, especially automotive manufacturers, in achieving their goals. We often address critical industry issues in a time- and cost-effective manner.

Our testing activities covers a wide variety of engine and component performance and durability tests, including full-load engine performance tests, durability tests for timing and other engine belts, high-temperature and thermal shock resistance tests, and specialized corrosion tests in different environments. We also offer high-cycle engine durability tests up to 1000 hours, pressure and vacuum resistance tests for individual components, and vibration tests up to 10 kN as part of our extensive engineering and laboratory services.

Since our founding, DinaMotors has been a leader in providing technical and engineering services, focusing on control and monitoring systems, failure analysis, and maintenance through oil analysis. We offer comprehensive services to a range of industries. Our key activities in this field include automation for monitoring and controlling powertrain performance and installing advanced sensors to read the operational conditions of engines and their components. These efforts contribute significantly to increasing system life and reducing human error.

In failure analysis and maintenance through oil analysis, we leverage a rich database containing over 2000 oil analysis reports for compression and spark ignition engines. This allows us to identify healthy engines, those needing maintenance, and those at risk of failure, reducing repair costs by up to 70% and optimizing spare part inventory. Using advanced tools like Fish Bone Diagrams and failure history analysis, we prevent issues before they occur, which plays an essential role in reducing repair times and enhancing system productivity.

Dinamotors Technical and Engineering Services