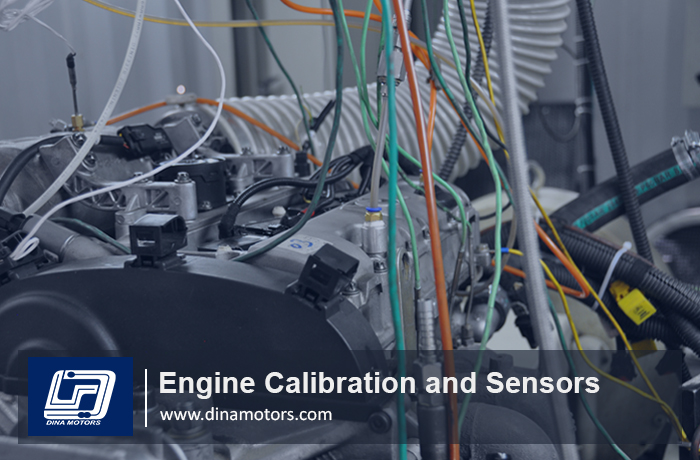

Development Tests Of Engine

Development tests of engine prototypes conducted on the dyno focus on the selection of individual components and engine systems, their optimization for a given application, verification of technological assumption tests created during the engine design stage on the real object, together with simulation tests. At this stage, engine control unit calibration works are conducted in parallel in order to provide full functionality of engine components.

.

Individual Engine Component And System Functionality Tests

Functionality tests of engine components and systems are conducted on the dyno in order to verify and assess the operational correctness of individual engine subassemblies. The verification is usually based on the result analysis delivered during durability tests conducted on the testing bench, together with assessments of wear of a given component, subjecting it to meteorological and material tests, as well as via visual inspection.

.

Sample Calibration Works

- injector mapping

- engine friction mapping

- power curve calibration

- combustion process stability optimisation

- fuel consumption and exhaust emissions optimisation

- calculated rotational torque (torque to quantity)

- actuator calibration, e.g. of EGR, TVA, VGT, etc.

- strategies to protect the engine against overloading and overheating

- air pulsation

- volumetric engine efficiency

- fuel injection and air flow strategy calibration