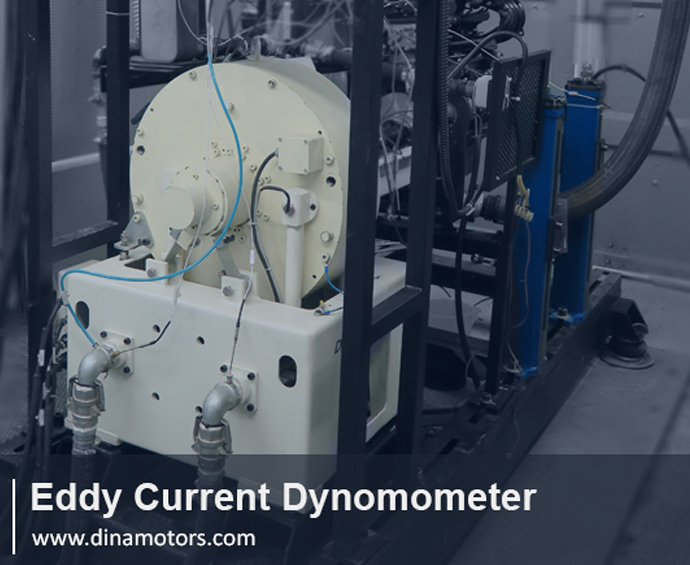

Eddy Current Dynamometer

A device for measuring engine power and torque

A dynamometer is used to measure the power and torque of any rotating engine (of internal combustion or electric types) or the force needed to rotate any mechanism. Suitable for all types of vehicle engines, the 190 kW Eddy Current Dynamometer is considered as one of the most hot-selling and easy-to-use products of Dynamotors.

Operating Principles

A dynamometer consists of two main parts:

- Rotor and Central Shaft: This part is connected to the engine through a coupling.

- Stator or Fixed Body: This part is suspended and connected to a loadcell through an arm.

It operates based on the eddy current (or Foucault current) principle. The stator is wound with coils and is energized by electricity, creating a magnetic field. The rotor is held by the stator using an electromagnetic braking force. The reaction force of the stator is measured using a loadcell. Torque is calculated by multiplying the force by the length of the arm.

Applications

The Eddy Current Dynamometer is suitable for measuring the power and torque of all types of combustion and electric engines.

Advantages

Technical Specifications

Below are 9 key technical specifications of the equipment:

- Length: 60 cm

- Width: 55 cm

- Height: 80 cm

- Weight: 400 kg

- Rotor Diameter: 450 mm

- Maximum Power: 190 kW

- Maximum Speed: 7500 RPM

- Power Supply: 110 V DC

- Maximum Torque: 600 Nm @ 1500 RPM

Accessories

The following accessories are required to fully operate this equipment.

Power Control Unit

This unit provides the DC voltage for the dynamometer. The input power for this unit is 220V AC, and it features an analog control input to manage the level of DC output. The controller sends an analog control signal to this power control unit under different engine operating conditions, which then provides the necessary DC power for the dynamometer.

Calibration Weights

The certified calibration weights from accredited laboratories are required to calibrate the dynamometer.

Installation and Packaging Information

install information

During engine installation on the dynamometer, care must be taken to ensure that the engine and dynamometer are aligned using precise measurement methods to prevent any misalignment, which could cause additional loads on the dynamometer bearings.

Deliverable Items:

- 190 kW Dynamometer

- Installed Engine Speed Sensor

- Installed loadcell

- Power Cable

- Coupling Guard

- Calibration Arm